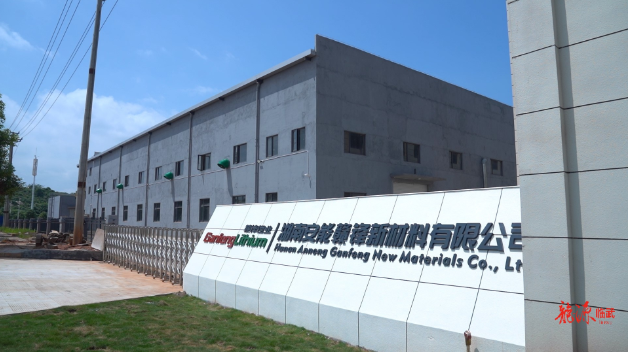

Recently, Hunan Aneng Ganfeng New Materials Co., Ltd. achieved a new breakthrough in lithium carbonate production capacity through technological transformation and equipment upgrading.

As the only enterprise in Linwu county that has already produced lithium carbonate, its monthly production capacity has increased from 600 tons to 800 tons, and the product purity is as high as 99.7%.

In the production workshop of the company, bags of high-purity lithium carbonate products are neatly stacked, which will be used as important raw materials in lithium battery manufacturing.

Since the trial production before the new year, the enterprise has achieved a stepwise growth in production capacity through continuous optimization of production processes.

Zhang Bowen, deputy general manager of quality of the Hunan Anneng Ganfeng New Materials Company, introduced that the company conducted trial production before the new year and discovered some problems during the process.

Specifically, there was a lag phenomenon in the pyrometallurgical process, and the conveying capacity of some belts and conveying equipment could not meet the current production capacity demand.

The company then decided to suspend the pyrometallurgical production line and upgrade technologies to optimize its performance. At the same time, the company's wet production line continued to produce lithium carbonate by purchasing intermediate products containing lithium brine.

The pyrometallurgical and hydrometallurgical processes are the main methods for producing lithium carbonate products in Anneng Ganfeng. The pyrometallurgical process obtains high-purity products through high-temperature calcination, while the hydrometallurgical process uses chemical extraction technology.

This year, the company has launched a technological renovation of the roasting workshop, comprehensively sorting and upgrading all the process pipelines in the workshop, and improving the full automation level of the production workshop.

“The technological transformation mainly focuses on the upgrading and transformation of production equipment to meet the predetermined production capacity targets. In the field of hydrometallurgical production, we have reached a global leading level. Since 2000, we have been deeply engaged in the research and application of hydrometallurgical process technology, and have experienced personnel in hydrometallurgical process,” said Zhang Bowen.

In addition, outside the factory, the company has also completed 98% of the road hardening and all greening work. The brand new production environment not only improves product quality, but also enhances employees’ work enthusiasm.

Zhang Bowen pointed out that if there are iron filings or other debris on the production scene that accidentally fall into the product, it will have a negative impact on product quality. By optimizing production site management, the probability of such problems can be effectively reduced, thereby significantly improving the level of product quality control.

The company currently has a production capacity of 800 tons per month, and will continue to gradually achieve the goal of producing 25,000 tons per year through technological upgrades.

“At present, the market price of lithium carbonate per ton is about 59,000 yuan. Adding the cost of anhydrous sodium sulphate, we can achieve a monthly output value of 50 million yuan. It means there will be considerable economic benefits over the entire year. At the same time, through the technological upgrade of the carbonization process, we want to directly produce high-purity lithium carbonate, laying a solid foundation for the long-term development of Linwu’s lithium battery industry,” said Zhang Bowen.

Chinese source: linwuxinwen

湘ICP备13003667号

湘ICP备13003667号