Hunan Nonferrous Xintianling Tungsten Industry Co., Ltd. is a key backbone subsidiary of China Minmetals Corporation and a national high-tech enterprise. Since 2024, the company has been committed to becoming a resource-saving and green demonstration tungsten mining enterprise based on technological innovation and green development, contributing to the high-quality development in the region. It was rated as the “Advanced Model” in the fourth quarter of 2024 in Chenzhou City.

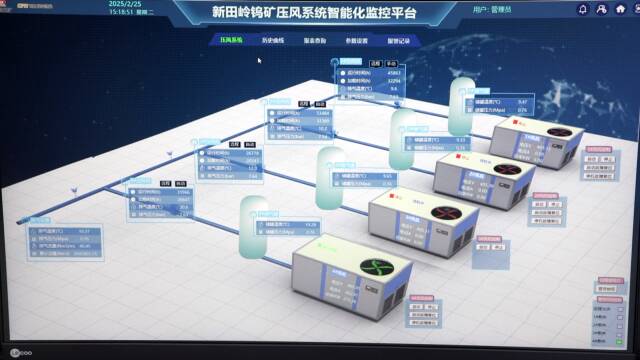

In 2024, the company made efforts to promote the enterprise transformation and upgrading based on intelligent construction. 15 million yuan has been invested to build a smart management platform for the entire life cycle of mining safety equipment, as well as multiple intelligent systems such as the underground 10 gigabit industrial ring network, which have met the national standards for intelligent demonstration mines.

Real-time data and images of each production process are displayed dynamically on high-definition large screens at the intelligent control center of the company. All kinds of data information, from deep well operations to complex equipment maintenance, are clear, greatly improving the operational efficiency and safety of the mine.

In addition, the company’s mining technology transformation project was completed in 2024. It has promoted the sustainable development of the company through measures such as optimizing production capacity distribution, improving transportation efficiency, energy conservation and emission reduction, and environmental protection.

After the completion of this project, the ventilation, drainage, transportation and other systems of the mine have been further optimized. The underground ore supply capacity has increased to 5,000 tons per day from 4,000 tons before, and the ore supply efficiency has increased by more than 25%. The production efficiency, safety and environmental protection level of the mine have been comprehensively improved.

The company has always adhered to green, low-carbon, and environmentally friendly production, and worked to promote technological innovation and application. In 2024, the two key technologies led by the company, namely “New Technologies and Applications for Clean and Efficient Utilization of Typical Skarn-type Scheelite” and “Key Technologies and Equipment for Large-scale Low-grade Green Intelligent Mining”, were respectively recognized as “International Advanced” and “International Leading”.

The tungsten beneficiation indicators and comprehensive utilization of tailings have reached international leading levels, and both have won the second prize of China Nonferrous Metals Industry Science and Technology Award. They are of great significance for the company to achieve the zero emission of tailings and build a green mine.

The comprehensive utilization of tailings, or where tailings go, includes the entire recycling, underground filling, and reuse into construction products. Currently, the overall recycling and reuse rate has reached over 76%, which is at the forefront of the industry.

In recent years, the company has made efforts to build safe and smart mines. In the future, it also plans to build a high-standard high-concentration filling diversion test production line, and accelerate the construction of the screening and reselection joint waste disposal project to solve the “bottleneck” problem in tailings disposal, in a bid to be a green mine with zero emission of tailings.

Chinese source: beihunews

湘ICP备13003667号

湘ICP备13003667号